Digital Textile Printers In India

Our advanced digital textile printers are engineered for peak performance, making us a leader in modern production. Orange O Tec’s innovative technology offers a superior fabric digital printer experience, ensuring vibrant, precise results every time. Our cutting-edge digital textile printing printer lineup is meticulously designed to meet the demands of high-volume operations, setting a new benchmark for the textile printing printer market.

Digital Textile Printing Printers for Businesses

Direct To Fabric Textile Printers

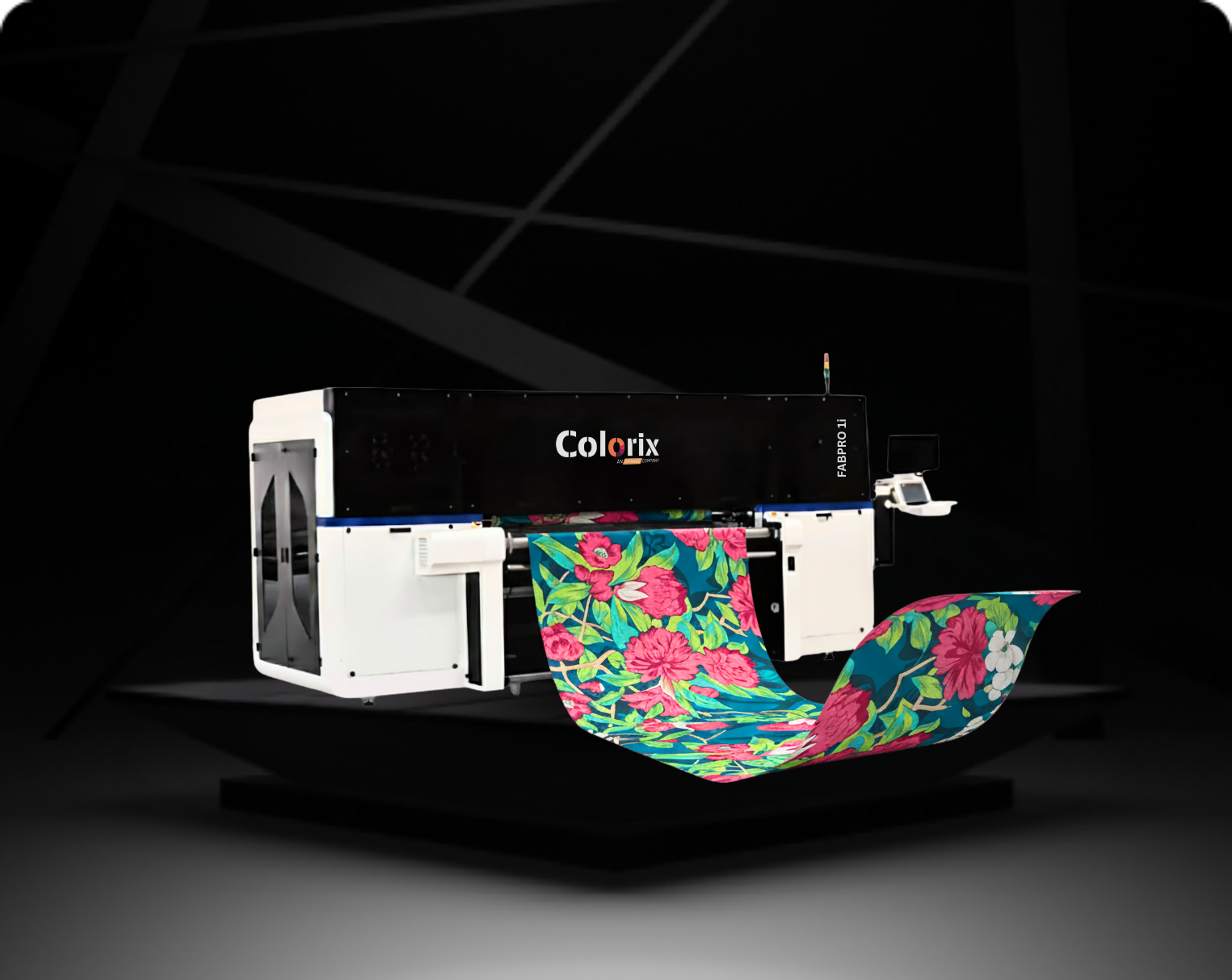

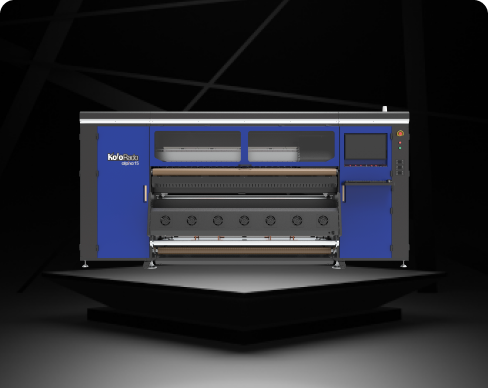

FabPro 1i (Made in India)

Production capacity: Upto 2,200 LM/Day

Number of Heads: 8

Printhead Type: Ricoh Gen 6

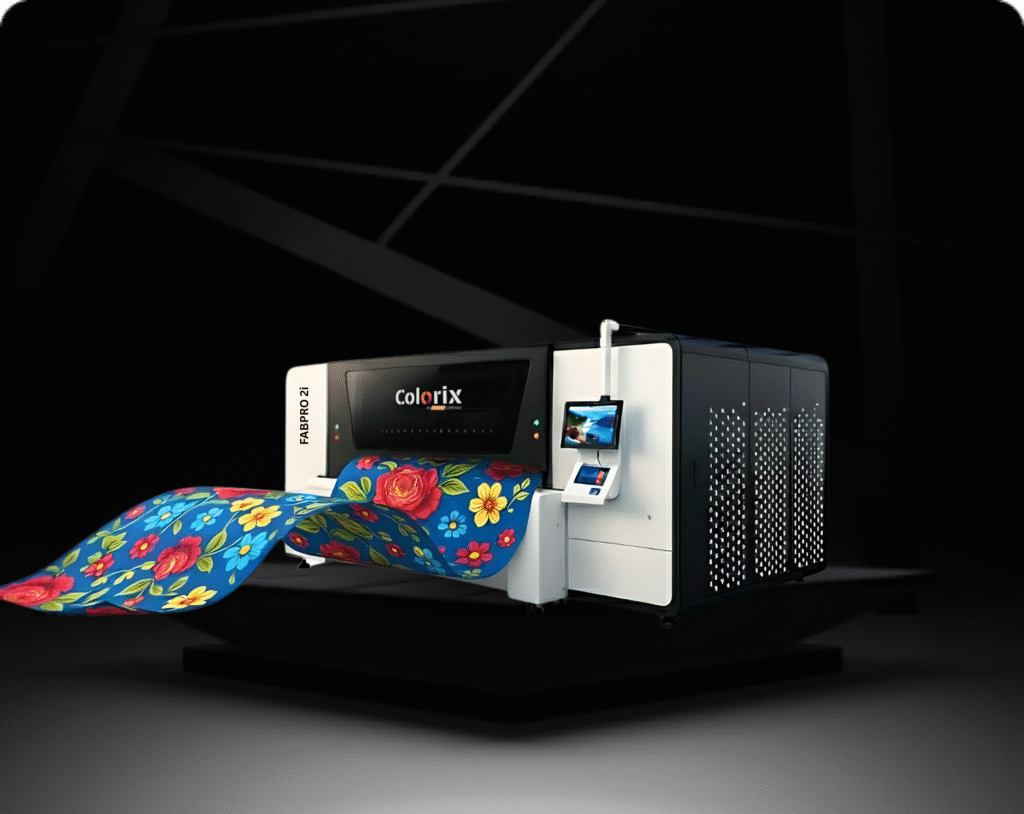

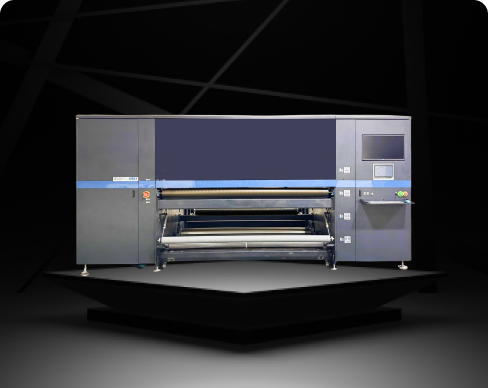

FabPro 2i (Made in India)

Production capacity: Upto 5,500 LM/Day

Number of Heads: 16

Printhead Type: Ricoh Print Head

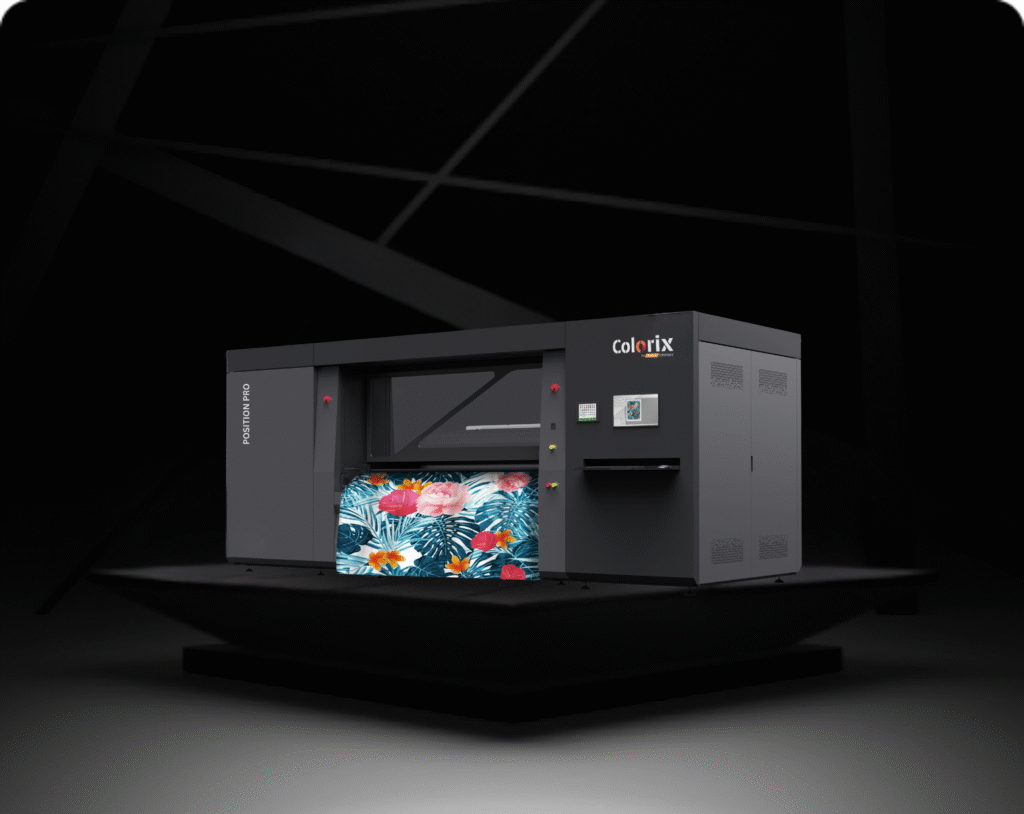

Position Pro

Production capacity: Upto 2,000 LM/Day

Number of Heads: 16

Printhead Type: Kyocera Print Heads

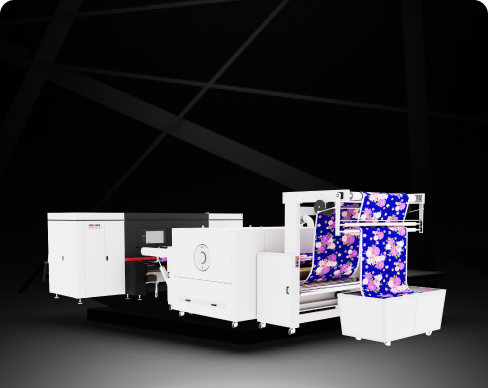

K24

Production capacity: Upto 5,000 LM/Day

Number of Heads: 16 to 24

Printhead Type: Kyocera

K64

Production capacity: Upto 15,000 LM/Day

Number of Heads: Configurable (32, 48, 56, 64)

Printhead Type: Kyocera Katana

K32

Production capacity: Upto 7,500 LM/Day

Number of Heads: 32

Printhead Type: Kyocera

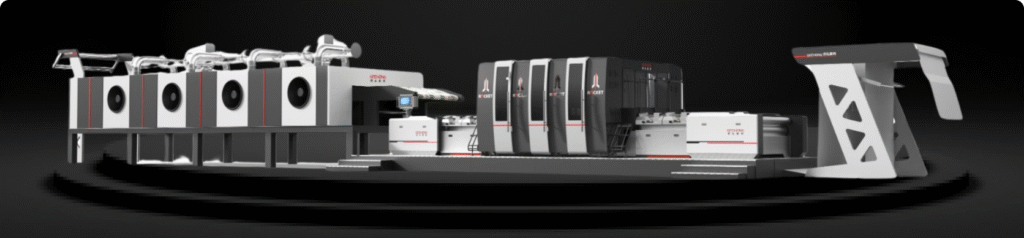

Rocket

Production capacity: Upto 60,000 LM/Day

Number of Heads:

ROCKET K – Up to 272

ROCKET X – Up to 128

Printhead Type: Kyocera Katana

JP7

Production capacity: Upto 6,800 LM/Day

Number of Heads: Scalable from 8 to 16

Printhead Type: Kyocera

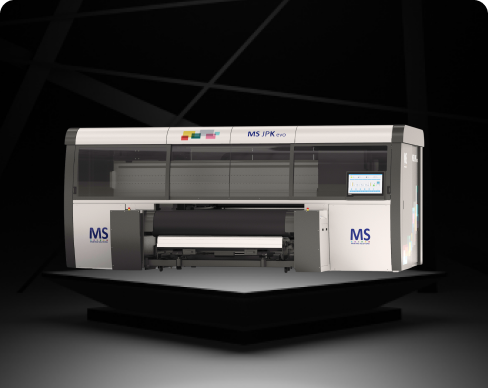

JPK Evo

Production capacity: Upto 1,100 LM/Day

Number of Heads: Scalable from 8 to 16

Printhead Type: Kyocera KJ4B

Minilario

Production capacity: Upto 21,800 LM/Day

Number of Heads: 64

Printhead Type: Kyocera

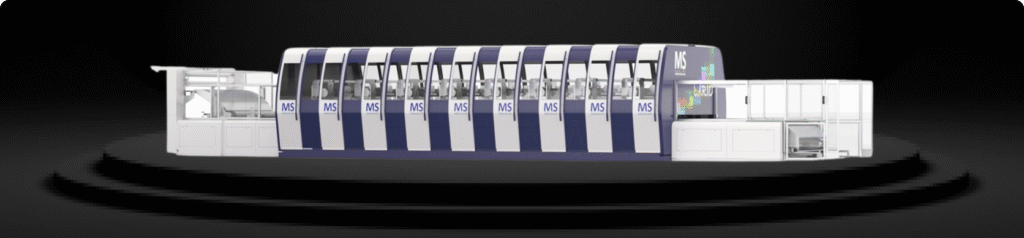

Lario

Production capacity: Upto 60,000 LM/Day

Number of Heads: Configurable – The number of heads varies depending on the printer setup

Printhead Type: Kyocera KJ4B Series Industrial Inkjet Heads

Sublimation Textile Printers

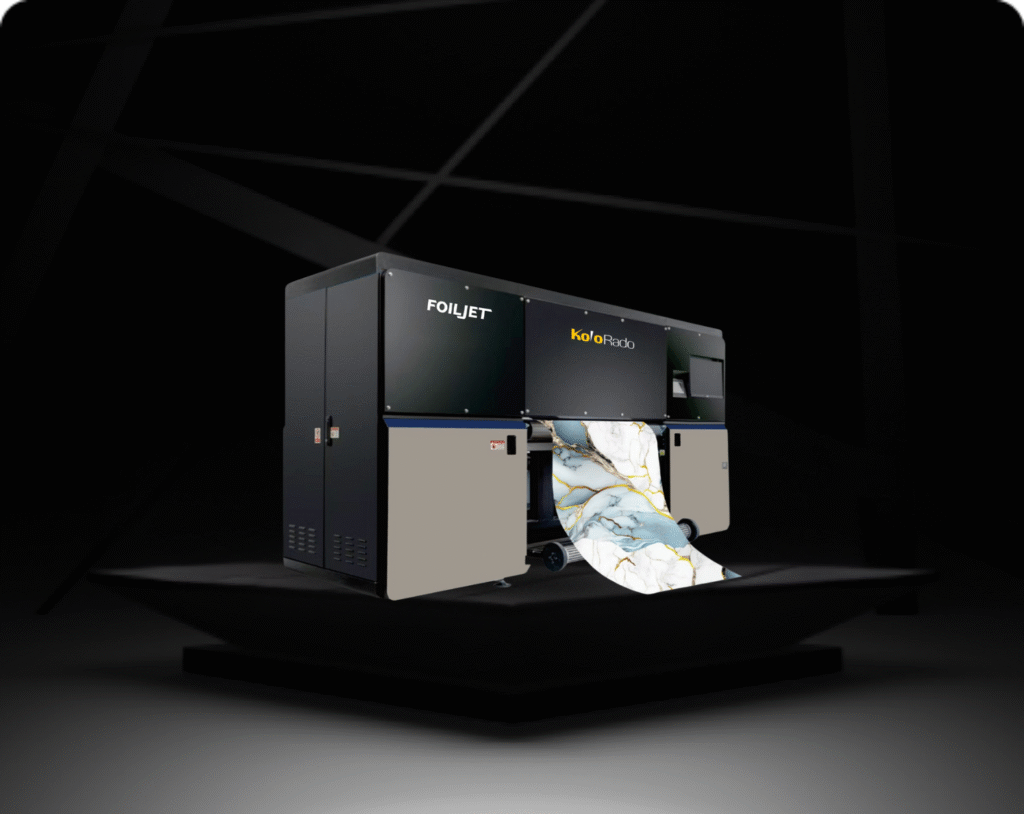

FoilJet 8 Head

Production capacity: Upto 2,200 LM/Day

Number of Heads: 8

Printhead Type: Epson I-3200 A1

FoilJet 16 Head

Production capacity: Upto 2,200 LM/Day

Number of Heads: 8

Printhead Type: Epson I-3200 A1

Alpha II

Production capacity: Upto 4,000 LM/Day

Number of Heads: 8

Printhead Type: Epson I- 3200 A1 Heads

Alpha III

Production capacity: Upto 6,400 LM/Day

Number of Heads: 12

Printhead Type: Epson I- 3200 A1 Heads

Alpha 15

Production capacity: Upto 5,100 LM/Day

Number of Heads: 15

Printhead Type: Epson I- 3200 A1 Heads

Alpha 16

Production capacity: Upto 9,200 LM/Day

Number of Heads: 15

Printhead Type: Epson I- 3200 A1 Heads

SubPro II

Production capacity: Upto 7,100 LM/Day

Number of Heads: 8

Printhead Type: Kyocera (Single/Dual Channel Optional)

SubPro S-16

Production capacity: Upto 19,500 LM/Day

Number of Heads: 24

Printhead Type: Epson I-3200 A1

Fusing

Pengda

Production capacity: Upto 15,000 LM/Day

Number of Heads: No Heads used for fusing printer

The Digital Revolution: Why Industry Leaders Choose Digital Textile Printers

The global textile landscape is transitioning into a future defined by speed and sustainability, and this change is led by the adoption of high-performance Digital Textile Printers. At Orange O Tec, we understand that the modern manufacturer requires more than just strong equipment; they need a competitive edge.

By integrating Digital Textile Printers into your production line, you unlock the ability to handle complex designs and rapid turnarounds that traditional methods simply cannot match. Our range of Digital Textile Printers is engineered to provide the highest DPI and color consistency, ensuring that every meter of fabric meets international quality standards.

Engineering Excellence in Every Digital Textile Printing Printer:

Choosing the right Digital Textile printing printer is the most significant investment a textile business can make in today's market. Each Digital Textile printing printer in our portfolio, from the high-speed Homer series to our specialized Colorix models, is built for 24/7 industrial reliability.

A robust Digital Textile printing printer eliminates the need for screen preparation, allowing for a drastic reduction in setup time and labor costs. When you partner with Orange O Tec, you are choosing a Digital Textile printing printer backed by a nationwide service network and a commitment to zero downtime.

Optimizing Production with the Modern Print Cloth Printer:

Efficiency in the factory floor begins with a Print Cloth Printer that can handle various substrates without constant reconfiguration. Our Print Cloth Printer solutions are designed with advanced fabric feeding and belt guiding systems to ensure seamless operation across cotton, silk, and polyester.

The precision of a modern Print Cloth Printer allows for "just in time" production, meaning you can print exactly what is ordered and reduce dead stock. Because every Print Cloth Printer we offer is calibrated for industrial scale, your business can grow from small batches to thousands of meters per day effortlessly.

Innovation at Scale: The Power of the Fabric Digital Printer:

The transition to a Fabric Digital Printer allows designers to experiment with an unlimited color gamut and photorealistic textures. A Fabric Digital Printer from our Green Edge series specifically addresses the need for eco-friendly production by utilizing pigment inks that require no post-washing.

This means your Fabric Digital Printer is not only producing world-class designs but is also saving significant amounts of water and energy. Using a Fabric Digital Printer empowers your brand to lead the market in both creative innovation and environmental responsibility.

Sustainable Growth Through Advanced Textile Printing Printer Technology:

The modern Textile printing printer is a marvel of green engineering, designed to minimize the carbon footprint of the garment industry. At Orange O Tec, our Textile printing printer solutions focus on reducing ink waste and power consumption through intelligent piezoelectric headtechnology.

Every Textile printing printer we install is a step toward a cleaner industry, as digital methods use up to 90% less water than traditional rotary printing. By choosing a Textile printing printer that prioritizes these efficiencies, you ensure your business remains compliant with global sustainability mandates while increasing your bottom line.

Versatility and Speed with the Textile Fabric Printing Printer:

A high-speed Textile fabric Printing Printer is the ultimate answer to the demands of fast fashion and rapid prototyping. Our Textile fabric Printing Printer options include multi-head configurations that can reach speeds of up to 60,000 linear meters per day.

The stability of a Textile fabric Printing Printer ensures that even at these incredible speeds, the print quality remains sharp and the colors remain vibrant. Investing in a Textile fabric Printing Printer allows your facility to replace multiple flatbed printers with a single, highly efficient unit that occupies a fraction of the floor space.

Precision Control: The Digital Printing Printer for Fabric:

The versatility of a digital printing printer for fabric is unmatched when it comes to handling diverse textile materials. Whether you are printing on delicate knits or heavy woven blends, a digital printing printer for fabric provides the tension control necessary to prevent stretching or misalignment.

Our digital printing printer for fabric lineup features advanced sensors and "head crash" protection to safeguard your investment during long runs. Because a digital printing printer for fabric is so adaptable, it allows your business to pivot between fashion, home textiles, and industrial applications with ease.

Quality Assurance with the Digital Cloth Printing Printer:

Maintaining the "hand feel" of a fabric is essential in the luxury market, and a Digital Cloth Printing Printer ensures the ink bonds perfectly without altering the material's natural texture. A Digital Cloth Printing Printer from Orange O Tec uses specialized chemistry that provides excellent wash fastness and durability.

The automated cleaning and maintenance cycles of a Digital Cloth Printing Printer ensure that the print heads stay in peak condition for years. When you deliver products created on a Digital Cloth Printing Printer, you are delivering a promise of quality that your customers will recognize instantly.

The Future of Manufacturing: Selecting Your Fabric Printing Printer:

Finding the perfect Fabric Printing Printer is about aligning technology with your specific business goals and production scales. A Fabric Printing Printer provides the flexibility to offer customized solutions to your clients, opening up new revenue streams in the personalized goods sector.

At Orange O Tec, we guide you through every step of selecting a Fabric Printing Printer, from initial consultation and installation to comprehensive operator training. The right Fabric Printing Printer will act as the engine for your company's expansion, helping you set new benchmarks in the vibrant world of Indian textiles.

Unlock the Future of Textile Printing

Experience unparalleled efficiency with Orange O Tec’s digital textile printers. Our technology ensures waterless production while maximizing output and minimizing environmental impact.

Eco-Friendly

Reduce water usage and embrace sustainable practices in your printing operations.

High Output

Achieve up to 60,000 linear meters of printing per day effortlessly.

FAQs

Q1: What is Orange O Tec?

Orange O Tec is India’s leading provider of digital solutions for the textile industry, specializing in the distribution and service of high-end Digital Textile Printers.

Headquartered in Surat, we represent world-class brands like MS Italy and Homer, offering every client a high-performance Digital Textile printing printer tailored to their specific needs. Our mission is to empower manufacturers by providing a reliable Print Cloth Printer that combines industrial speed with eco-friendly technology.

Q2: What makes Orange O Tec a leader in the digital textile industry?

Our leadership stems from our ability to provide a comprehensive Fabric Digital Printer ecosystem that includes hardware, software, and technical support. We are not just vendors; we are partners who help you select the right Textile printing printer to optimize your production.

By choosing Orange O Tec, you gain access to a Textile fabric Printing Printer that is backed by the largest service network in the country, ensuring your operations never skip a beat.

Q3: Can I use a single Print Cloth Printer for different types of fabric?

Yes, versatility is a core feature of the technology we provide. A professional Print Cloth Printer from our lineup can be configured to handle a wide range of substrates, from natural cottons and silks to synthetic polyesters. Depending on the ink type and printer model, your Print Cloth Printer can pivot between different fashion and home decor projects with minimal downtime.

Q4: How does a Fabric Digital Printer help in reducing production costs?

A Fabric Digital Printer eliminates the expensive and time-consuming process of screen making and color separation. By using a Fabric Digital Printer, you reduce water consumption by up to 90% and ink wastage significantly.

This makes the Fabric Digital Printer the most cost-effective solution for short runs, sampling, and high-detail custom orders where traditional methods would be too costly.

Q5: What kind of support do you provide after I purchase a Textile printing printer?

We believe the sale is just the beginning of our relationship. Every Textile printing printer we install comes with comprehensive operator training, professional calibration, and access to our 24/7 remote diagnostic support.

With service hubs across India, our engineers ensure that your Textile printing printer maintains maximum uptime and consistent output quality throughout its entire lifecycle.

Q6: Is a digital printing printer for fabric suitable for high-volume industrial production?

Absolutely. While many associate digital with small batches, a high-speed digital printing printer for fabric like our MS Lario or Colorix series can reach production speeds that rival or exceed traditional rotary printing. A modern digital printing printer for fabric is built for 24/7 industrial use, providing the massive scale you need without the design limitations of traditional methods.

Q7: What are the environmental benefits of using a Digital Cloth Printing Printer?

A Digital Cloth Printing Printer is a cornerstone of sustainable manufacturing. By utilizing “dry” processes and pigment inks that require no post-washing, a Digital Cloth Printing Printer drastically cuts down on chemical discharge and water pollution. Transitioning to a Digital Cloth Printing Printer helps your brand align with global ESG goals and eco-conscious consumer demands for a cleaner future.

Q8: How do I choose the right Fabric Printing Printer for my business?

Choosing the right Fabric Printing Printer depends on your desired production volume, the type of fabric you use, and your specific end-market. Our experts evaluate your requirements to recommend a Fabric Printing Printer that balances speed and resolution perfectly.

Whether you need a starter unit or an industrial-grade Fabric Printing Printer, we provide the technical guidance to ensure your investment drives long-term growth.